Your Guide to Selecting a Construction Debris Chute

A construction debris chute is a vertical or near-vertical tube system that channels waste materials from upper floors directly to ground-level collection points using gravity. These modular systems help construction teams remove debris quickly while reducing labor costs and improving worksite safety.

A complete system is made of several parts working together. Cylindrical chute sections, usually 3-4 feet long, stack vertically to form the main channel. At each floor, intake hoppers provide access points for loading debris. To hold everything in place, support frames and outriggers anchor the chute securely to the building. At the bottom, a discharge end directs the waste into a dumpster or truck.

You have two primary material options. Plastic, specifically HDPE, is lightweight and works well for roofing and light demolition. For high-rise buildings and extreme conditions, heavy-duty steel provides superior durability.

Managing construction waste efficiently makes the difference between a project that stays on schedule and one that falls behind. When debris piles up on upper floors, your crew spends time hauling materials down stairs or waiting for elevators. That time adds up fast. A debris chute system eliminates these bottlenecks and creates a safer work environment by keeping pathways clear and reducing the risk of falling objects.

The construction debris containment systems market reached $1.2 billion in 2022 and continues growing as more contractors recognize the time savings these systems deliver. Studies show that debris chutes can cut waste removal time by up to 50%, translating to faster project completion and lower labor costs.

At SBI Contracting, we have spent years managing construction projects where coordinating efficient debris removal with construction debris chute systems has been part of keeping our jobs on schedule and our sites safe. This guide will walk you through what you need to know to select the right chute system for your project.

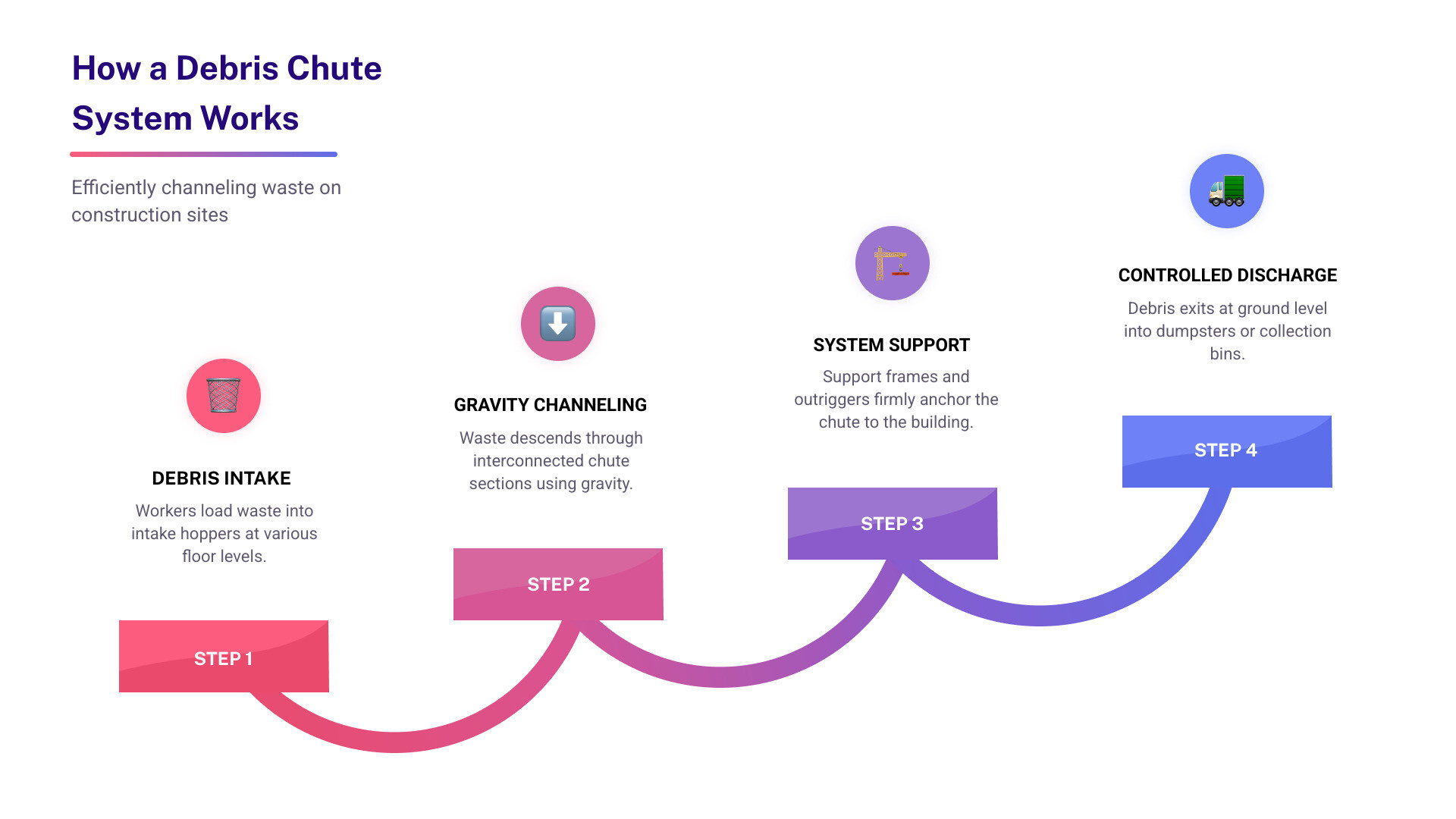

Understanding the Anatomy of a Construction Debris Chute System

Construction debris chutes are assemblies for the quick evacuation of materials from an elevated work location, using gravity to guide the flow of waste into a collection bin. This gravity-fed operation is simple and effective. Chute systems allow access at every floor and roof level, enabling workers to deposit trash directly into a dumpster at the bottom. This process contains waste, streamlining the job site and preventing debris from scattering. The design reduces the risk of accidents caused by falling debris by safely channeling waste materials. It accelerates waste disposal, cutting down the time required to transport debris from higher levels.

When you think about the flow of a construction project, the removal of waste often becomes a bottleneck. With a planned chute system, you transform waste removal into a smooth, continuous process. This leads to improved site efficiency, allowing your team to focus on construction tasks rather than laborious hauling. The Chutes Selection Guide provides further details on system design and selection.

Core Components You Need to Know

A debris chute system relies on several interlocking parts. The chute sections are cylindrical units made from durable materials like high-density polyethylene (HDPE) or steel. These sections stack vertically, forming the pathway for debris. Intake hoppers act as the access points, allowing workers to insert debris from different levels of your building. These hoppers are strategically placed for convenient and safe loading. To keep the entire system stable, an anchoring system is indispensable. This includes support frames and outriggers that firmly attach the chute to the building’s structure. The discharge end, located at the bottom, directs the debris into a designated collection area, a dumpster or truck. Each component is designed with specific dimensional specifications, including length, thickness, diameter, and weight, ensuring the system can handle the demands of your project. You can find more information about our products and how they contribute to efficient waste management by exploring More info about our chute products.

Essential Accessories for Improved Functionality

Beyond the core components, a range of accessories improves the safety, efficiency, and longevity of your debris chute system. Winches are used for lifting and lowering chute sections during installation and dismantling, simplifying the process. Protective liners, often made of steel, can be inserted into the chute sections in high-wear areas or where heavy, abrasive debris is common. These liners extend the life of the chute by protecting its primary material from excessive wear. Dust gaiters help contain dust and fine particles, which is useful in urban environments or occupied buildings. Safety flaps and hopper retainer bars secure the intake hoppers, preventing spillage and ensuring that debris only enters the chute when intended. Hopper stands provide stable support for intake hoppers, making them accessible and safe for workers. For the physical assembly and manipulation of chute sections, lifting chains allow for precise positioning and secure connections. These accessories transform a basic chute into a comprehensive waste management solution.

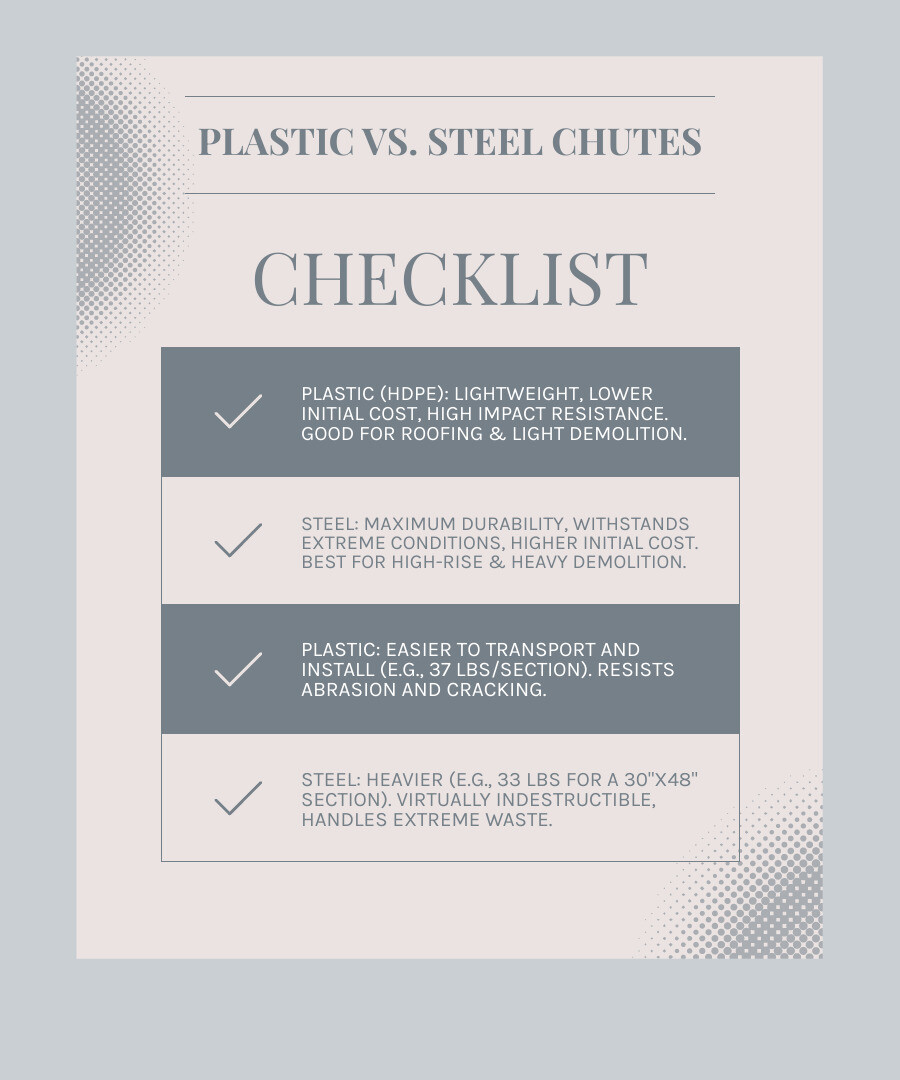

Choosing Your Material: Plastic vs. Steel Construction Debris Chutes

Selecting the right material for your construction debris chute is a decision that impacts durability, cost, and suitability for your project. Construction trash chutes are available in steel and heavy plastic, each offering distinct advantages. Your project’s requirements, including the type and volume of debris, the height of the building, and environmental conditions, will guide this choice. For a closer look at these options, we invite you to explore our External Plastic and Steel Chutes.

Here is a comparison to help you understand the differences:

| Feature | Plastic (HDPE) Chutes | Steel Chutes |

|---|---|---|

| Durability | High impact-resistant, resists abrasion and cracking | Virtually indestructible, withstands extreme conditions |

| Initial Cost | Generally lower | Generally higher |

| Weight | Lightweight (e.g., 37 lbs per section) | Heavier (e.g., 33 lbs for a 30″x48″ section) |

| Best Use Case | Light-duty construction, roofing, renovation, multi-story access | Heavy demolition, high-rise buildings, extreme conditions |

| Maintenance | Regular inspection, cleaning, replacement of damaged sections | Regular inspection, often coated for corrosion resistance |

High-Density Polyethylene (HDPE) Plastic Chutes

High-density polyethylene (HDPE) plastic chutes, like the DURACHUTE™ system, are lightweight and easy to install. Made from high-impact-resistant, high-density/high-molecular-weight polyethylene, these chutes offer resistance to impact and abrasion. This material’s resilience allows it to maintain its shape even when handling heavy or bulky debris. Plastic chutes are a fit for lighter demolition, roofing projects, and new construction where multi-story access is needed. They are easy to install and disassemble, which translates into savings in time and production costs for your project. Some plastic chutes are designed to ship and store flat, offering an economical and lightweight option for debris removal. This feature makes them convenient for projects where space is at a premium or frequent transportation is required. Their flexibility and durability make them a preferred choice for many light-duty construction and renovation jobs. For more details on these systems, refer to our page on Trash Chutes for Construction.

Heavy-Duty Steel Construction Debris Chutes

When your project demands strength and resilience, heavy-duty steel chutes are the solution. These systems are designed for durability, making them the choice for high-rise buildings, heavy demolition, and extreme construction conditions. Steel chutes are engineered to be virtually indestructible, offering dependable service throughout the duration of your job. The robust nature of steel allows these chutes to withstand nearly any type of debris, including large, jagged, or heavy materials. For projects involving significant demolition, steel chutes can be implemented with a baffle system. This feature helps break apart larger pieces of debris as they descend, minimizing the space needed for disposal and maximizing the utilization of your dumpsters. Steel systems are built to last, providing a steadfast solution for the most demanding waste removal challenges on your job site.

How Construction Debris Chutes Boost On-Site Efficiency and Safety

Implementing a construction debris chute system changes how waste is managed on your site. It reduces labor time because your crew no longer needs to manually carry debris down stairs or wait for service elevators. This efficiency contributes to faster project completion. Imagine the cumulative time saved across multiple floors and weeks of work. These systems also ensure a cleaner worksite by channeling all waste directly into a container, minimizing scattering and keeping pathways clear. This organized environment contributes to a lower injury risk, creating a safer space for everyone on site.

Maximizing Your Return on Investment

The financial benefits of using debris chutes make them a sound investment for a construction project. The first effect is on labor cost savings. By automating the vertical transport of waste, you reduce the need for workers to spend time and energy on debris removal, freeing them up for skilled tasks. This leads to a reduction in cleanup time; studies indicate that debris chutes can cut waste removal time by up to 50%. This efficiency contributes to faster project completion, which means earlier revenue generation and reduced overhead costs. Our experience shows that when debris removal is fast and hassle-free, overall productivity on the job site increases. Workers spend less time on non-productive tasks and more time on building. This streamlined process makes debris collection easy, providing a clear return on your investment. You can learn more about efficient waste management solutions by visiting our page on Garbage Chutes.

A Safer Worksite for Everyone

Debris chutes play a role in creating a safer construction environment. The controlled descent of debris through a chute system minimizes falling object hazards. Instead of materials being tossed or carried, they are guided securely from upper levels to the ground, preventing accidental drops that could injure workers or passersby below. These systems also reduce physical strain on your crew. Eliminating the need to carry heavy loads down multiple flights of stairs or across uneven terrain lessens the risk of back injuries, sprains, and other musculoskeletal issues. This commitment to safety aligns with industry guidelines, including those from the Occupational Safety and Health Administration (OSHA) standards. By channeling waste safely and efficiently, debris chutes protect your team and contribute to a healthier, more productive worksite.

Installation, Safety, and Compliance

Proper installation, diligent safety practices, and adherence to regulations form the foundation of an effective debris chute system. Without these elements, even an advanced chute can pose risks rather than solve problems. Proper anchoring ensures the system remains stable under load, regular inspection catches wear and tear before it becomes critical, and thorough user training empowers your team to operate the chute safely. These combined efforts align with regulatory standards, ensuring a secure and compliant operation.

Best Practices for a Secure Installation

A secure installation is needed for the safe and efficient operation of any construction debris chute. Before beginning, always barricade the work area at ground level to protect anyone below. Your team must wear proper safety gear and fall protection, including a full-body safety harness and lanyard, attached to an independent lifeline or structurally sound point. Ensure the building’s structural integrity, whether a parapet, roof, or scaffolding, can support the total weight of the chute system. Inspect all components for damage before and during assembly, looking for any signs of wear that could compromise safety. Maintain constant communication, either eye contact or radio contact, between workers at different work areas to coordinate movements. Tie the chute system securely to the structure at every hopper and at intermediate intervals to prevent excessive movement. When using a winch, ensure at least three wraps of cable remain on the drum and that the cable is wrapped securely and neatly. The chute must be hoisted in a vertical line, keeping all hooks, eye nuts, and chains straight. The DURACHUTE™ Installation Manual offers detailed instructions that we follow.

Adhering to Safety and Regulatory Standards

Operating a construction debris chute requires following safety and regulatory standards to protect workers and the public. In the United States, chutes may comply with guidelines like OSHA Part 1926.856, which outlines requirements for material removal, and NFPA 82, a standard from the National Fire Protection Association (NFPA) guidelines for waste and linen handling systems. These standards cover aspects like chute design, fire safety, and operational procedures. Beyond federal regulations, local permits and codes in Boise, ID, also dictate specific requirements for debris chute installation and use. Always consult with local authorities to ensure full compliance. A safety practice involves barricading the disposal area at ground level to prevent unauthorized access and protect individuals from falling debris. Educate all workers on the proper use of the chute system, emphasizing that it is for construction waste materials only, not hazardous substances. By following these standards and practices, you ensure a safe and legally compliant worksite.

Maintenance for a Long-Lasting System

Consistent maintenance extends the lifespan of your construction debris chute and ensures its safe operation. Implement pre-use checks before each workday, inspecting all load-bearing elements, chain assemblies, screw jacks, and clamps for proper operation and any signs of wear or damage. This proactive approach helps identify potential issues before they escalate. Regular cleaning procedures are also part of maintenance. While chutes are designed for debris, accumulation can occur, leading to clogs or increased wear. If a clog occurs, stop use immediately and clear the obstruction before introducing more debris. Never enter the chute to clear an obstruction; use appropriate tools from outside the system. Component replacement is another aspect of maintenance. Damaged sections, worn protective liners, or faulty winch cables should be replaced promptly. We recommend a thorough wear and tear inspection at the end of every job and an inspection at least once a year to assess the system’s overall integrity. Additionally, remove the chute from the dumpster each night due to the flammability of certain plastic materials, further enhancing site safety.

Making the Right Choice for Your Project

When considering a debris chute system, your choice involves evaluating factors beyond immediate needs. You weigh financial considerations, how frequently you will use the system, its reusability, and its potential for waste segregation. Each of these aspects plays a role in determining the right solution for your projects.

The Financial Equation: Rent or Buy?

The decision to rent or purchase a debris chute system comes down to the frequency and duration of your projects. For short-term projects or those with infrequent debris removal needs, renting a chute system can be a financially sound solution. Rental options provide flexibility, allowing you to access the necessary equipment without the upfront capital investment or the long-term responsibilities of storage and maintenance. Many providers offer turnkey rental solutions, including erection, dismantling, delivery, and pickup, simplifying the logistics for your team. External trash chute rentals are available for construction sites on a monthly basis, providing a flexible option. If your company undertakes numerous projects requiring debris chutes, purchasing might prove more economical over time. While the initial purchase cost is higher, owning the equipment can reduce overall expenses for frequently used items. This approach also gives you immediate access to the equipment whenever needed. When considering this financial equation, assess your project pipeline and historical usage to determine whether rental or purchase costs align better with your operational model. For permanent waste management solutions in multi-unit buildings, exploring options like Apartment Trash Chutes can offer valuable insights into long-term installations.

Modern Innovations and Environmental Responsibility

Modern debris chute systems are incorporating innovations that address both efficiency and environmental responsibility. Reusable systems are becoming more common, moving away from single-use components and reducing waste generated by the equipment itself. For instance, some systems are crafted from robust, woven-coated polypropylene material, with each 10-foot section weighing only 3 pounds. This lightweight design simplifies handling and transportation and contributes to the reusability factor. The construction and demolition (C&D) waste generated globally is substantial, representing 30-40% of all waste. Choosing systems made from lightweight, recyclable materials, like high-density polyethylene or stainless steel, helps mitigate this environmental impact. These materials are durable and can be recycled at the end of their lifespan, contributing to sustainable construction practices. Opting for such systems aligns with a commitment to reducing your environmental footprint and helps manage the volume of C&D waste more responsibly. The shift towards solutions that prioritize reusability and recyclable components reflects a growing awareness within the industry, as shown by companies like iHaulJunk, Inc. that champion efficient waste removal.

Let’s Get Your Project Started

Choosing the right debris chute system is a decision that impacts your project’s efficiency, safety, and budget. We understand that every construction site has unique demands, from the type of debris to the building’s height and specific logistical challenges. We focus on a thorough project needs assessment, working with you to understand every detail.

At SBI Contracting, we are a Division 10 construction company based in Boise, ID, since 1989. As the exclusive dealer of Chutes International in Idaho, a brand recognized for quality and innovative design, we can provide insights into design elements that work well and common issues to avoid. This ensures you receive a system that performs optimally.

Whether you are looking to rent a temporary construction debris chute for a short-term renovation or invest in a permanent solution for a new development, we are here to guide you through the selection and installation process. We offer a wide range of products and installation services, ensuring a timely, clean, and efficient completion for your project. Let us help you streamline your waste management and improve your worksite’s safety and productivity. Explore our comprehensive chute solutions today.